Home › Forum › Ask A Member › Ugly Duckling

- This topic has 74 replies, 15 voices, and was last updated 8 years, 3 months ago by

paulfromyork.

-

AuthorPosts

-

November 24, 2016 at 12:47 am #47932

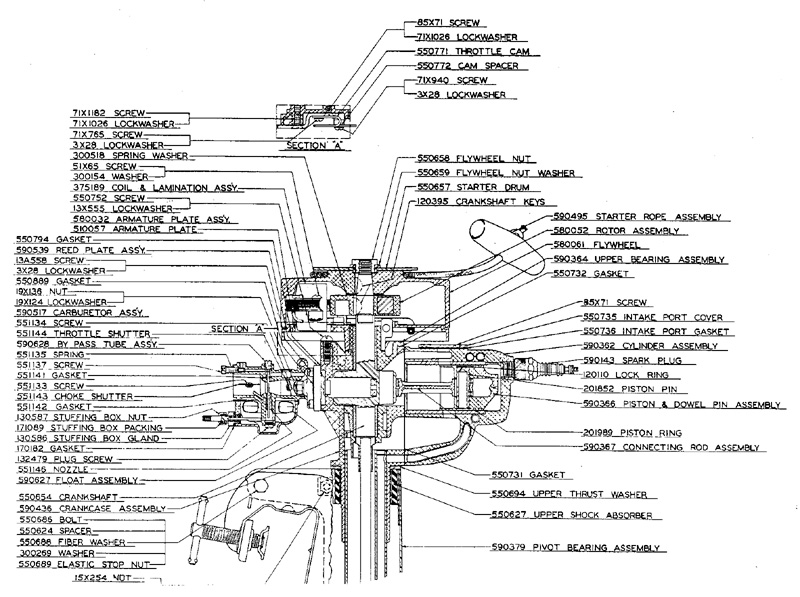

I pulled the flywheel and attached my meter neg cable to the ground and pos to both leads. The lead to the points shows continuity but the plug wire side is dead. I checked at the plug wire at the boot and where it emerges from the coil. Did I check it correctly?

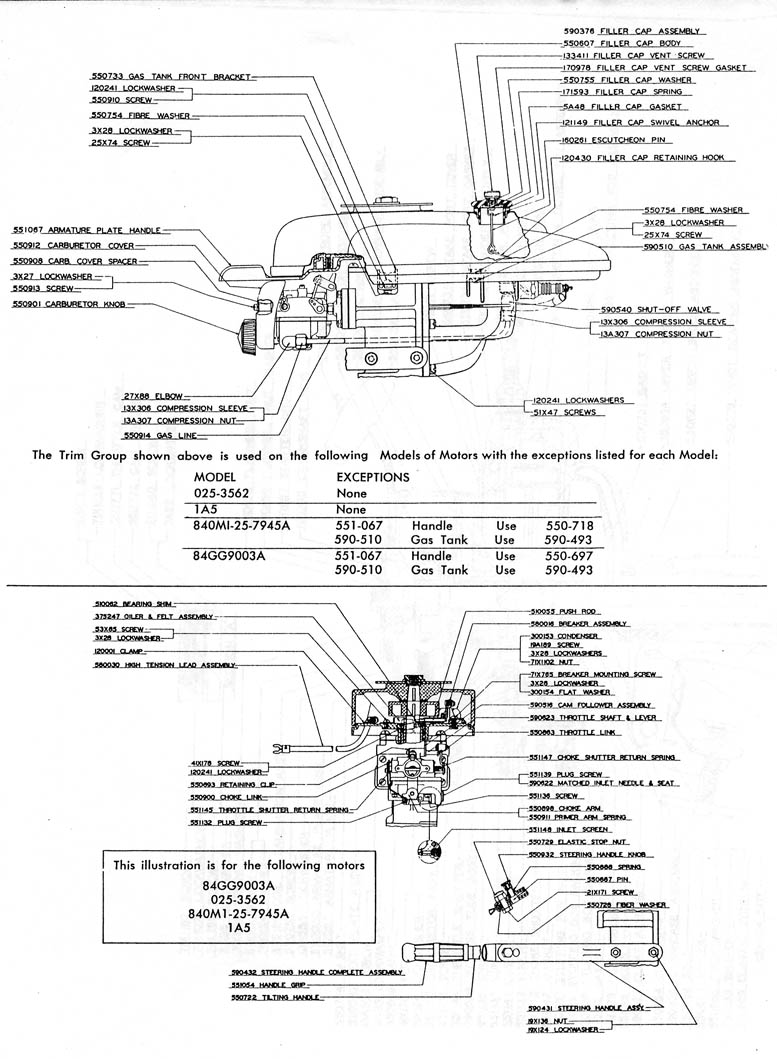

November 24, 2016 at 1:48 am #47936richardparquette site download shows Eaton Viking 1948-49 1.5 coil and lamination is PN#375189

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonNovember 24, 2016 at 1:51 am #47937bullie- i sent you a email -Jim PSB

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonNovember 24, 2016 at 2:04 am #47939Those coils were made before they figured out how to make them last only five years. It probably is ok. Remove the points and take them apart, degrease, then polish each contact shiny bright. Put it back together, set points to .020", and it probably will have spark.

November 24, 2016 at 2:11 am #47940quote Bullie:I checked at the plug wire at the boot and where it emerges from the coil.Here you are only checking your plug wire and not the coil. The plug wire from the coil terminal to the spark plug connector should have almost 0 resistance. Just a few ohms. To check the coils secondary windings, connect your meter to the ground wire and the spark plug wire terminal on the coil. Depending on your meter, it will probably need to be set to the 20K range to test the coil and to the 200 range to test the plug wire. The coil reading should be in the low thousands.

November 24, 2016 at 2:49 am #47943I will clean everything up and check again.

Bullie wrote:

I checked at the plug wire at the boot and where it emerges from the coil.I don’t know if I am confused or if I confused you guys with that. ^^^ I had my Neg clamp on the ground wire and checked for resistance with the pos lead at the boot first. Then, getting no reading, I also checked where the lead emerges from the coil so to confirm that it wasn’t just a bad spark plug wire.

November 24, 2016 at 2:58 am #47944November 24, 2016 at 3:43 am #47945Good stuff! Thanks.

November 24, 2016 at 2:50 pm #47956quote Bullie:I decided to revisit this little jewel. No spark. I pulled off the tank and the flywheel. I believe the coil is bad. What do I need to look for?Just looking at the coil does not indicate if the coil is good, unless the covering is cracked and peeling.

Doug Penn did a nice job of explaining how to use a analog meter to test if the primary and and secondary windings of a coil are good.

November 24, 2016 at 3:28 pm #47959quote cajuncook1:quote Bullie:I decided to revisit this little jewel. No spark. I pulled off the tank and the flywheel. I believe the coil is bad. What do I need to look for?Just looking at the coil does not indicate if the coil is good, unless the covering is cracked and peeling.

Doug Penn did a nice job of explaining how to use a analog meter to test if the primary and and secondary windings of a coil are good.

This test is exactly what I have stated that I did to determine the coil was bad.

-

AuthorPosts

- You must be logged in to reply to this topic.