Home › Forum › Ask A Member › ’57 Johnson 10hp Water Pump Leaking

- This topic has 12 replies, 8 voices, and was last updated 1 year, 4 months ago by

aquasonic.

-

AuthorPosts

-

August 2, 2024 at 5:47 pm #289588

I am rebuilding a 1957 Johnson QD18 10Hp. I got the water pump kit for that motor, and after putting it together the water pump does indeed pump water. My issue is that the top of the pump housing leaks around the driveshaft a fair amount. There is no “seal” in the pump housing top for the driveshaft, no o-ring. There is no seal or o-ring that goes on the outside of the housing either. The only o-ring goes at the top of the driveshaft where it mates with the powerhead.

So, is this leakage normal as long as there is water flowing from the water tube? Is it a sign that the pump housing is too worn?

What do you think? Let me have your feedback,

Thanks,

Dave

'57 Johnson QD18 10hp

'53 Sea King 3hpAugust 2, 2024 at 7:15 pm #289589if you installed the correct pump housing I would not worry about it unless engine cooling is affected.

Joining AOMCI has priviledges 🙂

August 4, 2024 at 6:41 am #289607At the top of the impeller housing there is no seal where the driveshaft passes through so some water will make its way through. I have had housings that were saltwater corroded at the driveshaft opening that had to be scrapped.

A good seal at the water tube grommet, clear passageways, a good housing and impeller, and you should have good water flow. Maybe run the motor and observe the spent cooling water. The OMC 10 hp should pump a lot of water.

Improvise-Adapt-Overcome

August 4, 2024 at 10:35 am #289610Am wondering how you have determined that water is leaking from the top of the impeller housing while pumping. Some of this “leakage” is normal and expected. Needless to say, excessive leakage from this area will diminish pump output to the powerhead. Excessive leakage is usually caused by grooving/pitting on the top surface of the impeller housing. Worn rubber on top of the impeller, poor impeller fit, or a damaged/distorted SS impeller plate will cause excessive leakage in this area as well. This is an area where it usually best to use OEM parts.

Like you say, there is no conventional seal on top of the water pump on this engine. The “seal” is the fit between the top of the impeller and the aluminum impeller housing. That being said, some leakage in this area is normal and expected.

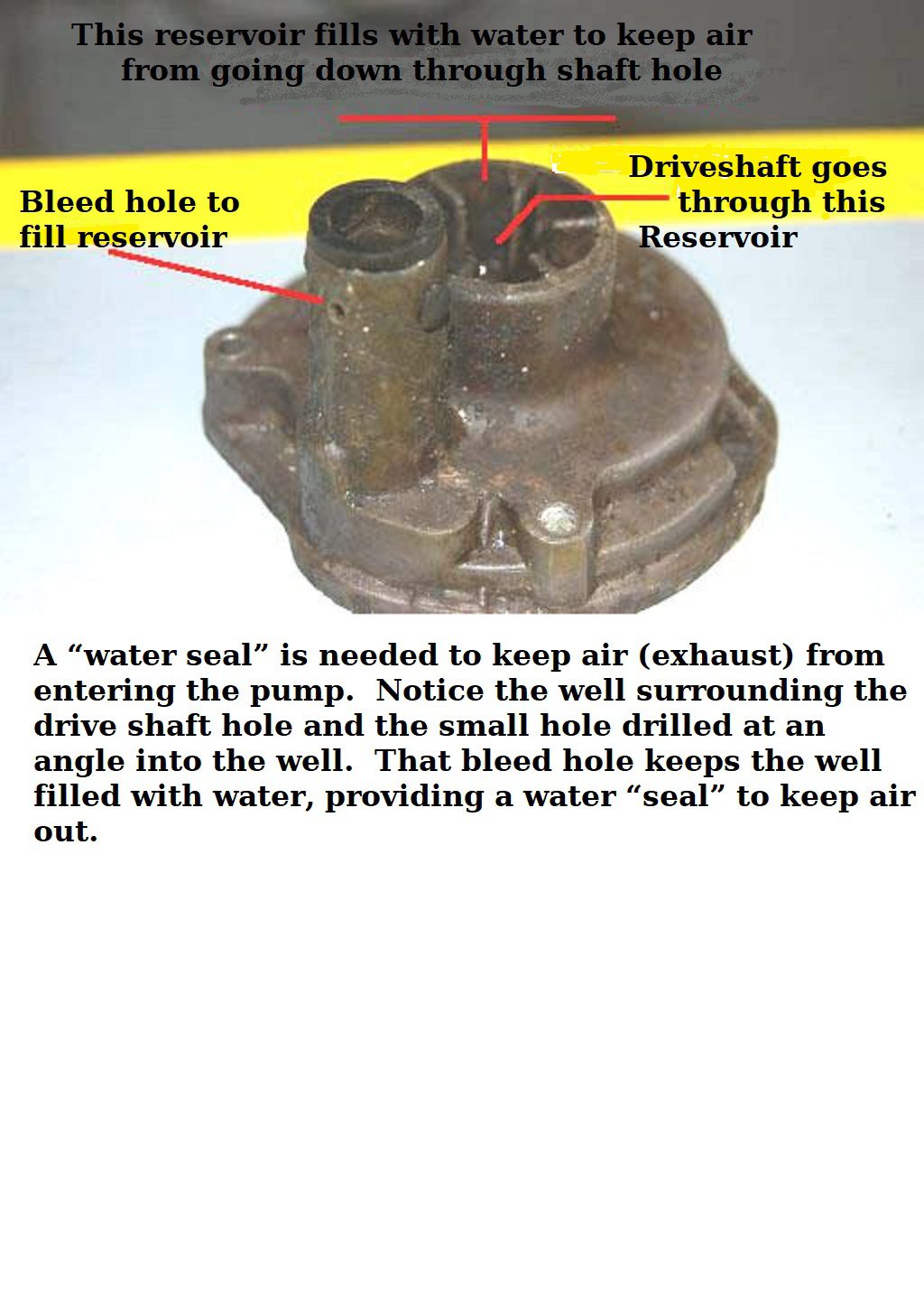

August 4, 2024 at 12:47 pm #289616Actually, there is another part to this subject. A “seal” is needed to keep air (exhaust) from entering the pump. Notice the well surrounding the drive shaft hole and the small hole drilled at an angle into the well. That bleed hole keeps the well filled with water, providing a water “seal” to keep air out.

2 users thanked author for this post.

August 4, 2024 at 2:37 pm #289618see bulletin on the subject

Joining AOMCI has priviledges 🙂

August 6, 2024 at 9:38 pm #289660And that is why we need ( and appreciate) Frank around here… Thanks Frank

Joe B

August 6, 2024 at 10:05 pm #289665And that is why we need ( and appreciate) Frank around here… Thanks Frank

Joe B

10-4 on that mister B!

dale

August 7, 2024 at 9:09 am #289669I thought Franks pictorial was a good one for my files, but

a little hard to read, so I redone it for my own use, but

thought I’d share it. Hope that’s okay Frank, and if I got

anything wrong, please let me know.Prepare to be boarded!

2 users thanked author for this post.

August 8, 2024 at 8:10 am #289701Great point indeed Frank!

-

AuthorPosts

- You must be logged in to reply to this topic.