Home › Forum › Ask A Member › Weak spark on 1973 20 Hp Johnson

- This topic has 72 replies, 13 voices, and was last updated 4 years, 8 months ago by

fleetwin.

-

AuthorPosts

-

July 17, 2020 at 11:28 am #208894

Hello All,

I am new to this forum. I am not sure my outboard is old enough to be in this Antique site. I picked up an old and beat up 1973 20 Hp Johnson (the first picture) and want to restore it.I have taken a part the power head and rehone the cylinder, both of them got 115/113 psi. The block has been sand blasted and paint back base color. So far I got done step #1.

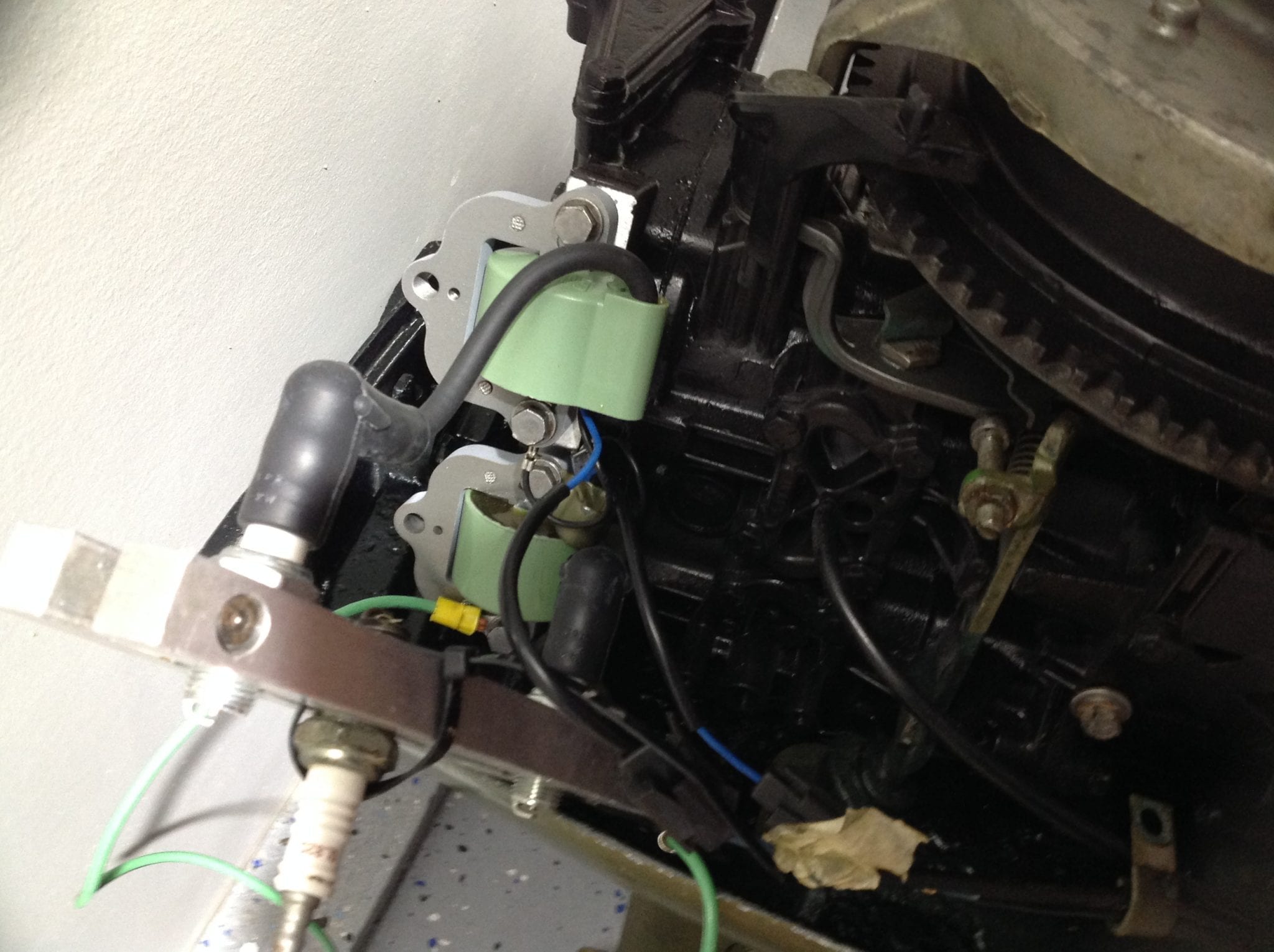

Step 2: Spark. It did not have spark so I have replaced two external ignition coils, new points and condensers. I got OK spark on the cylinder #2 and intermittent spark on cylinder #1 (sometime no spark at all). I have set the gap of 0.020″. The only thing I did not replace is the Charging Coil 581130 (Driver Coil). There is only one charge coil on OMC Armature Plate Assembly. Does it have 2 independent coil inside for each cylinder or only one for both? Does the point gap (0.020″) affect the spark quality?

Do I need to replace the Charging coil too?

All opinions and helps are welcomed.-

This topic was modified 4 years, 11 months ago by

Evinrude 25.

-

This topic was modified 4 years, 11 months ago by

Mumbles.

Mumbles.

July 17, 2020 at 12:43 pm #208912OK, well you have the infamous OMC “low tension ignition system”….Kind of a “hybrid” between the original OMC universal magneto and the CDII system that would come in 1977. This system is often hated, mostly due to a lack of understanding…

Yes, I would update/change that driver coil unless it seems relatively new, there was many internal changes/improvements made to that piece. The driver coil is a single winding that generates the primary voltage for both coils. But, before you replace it, you need to check for side to side slop on the magneto plate, this is a common problem. If the mag plate is sloppy from side to side, or up and down, point gap will vary and ignition output will be poor. The other issue is the air gap between the driver coil laminations and the flywheel magnets. This must be properly set with an alignment tool. Slop in the mag plate will also result in having the flywheel magnets rub on the driver coil. But, if the driver coil is set in too far from the flywheel magnets, primary output will be weak also.

Sounds like you already have replaced the the external coils. But, there are a few other things to consider. First, there is a black ground strap the runs from the mag plate to a good ground on the block. This should be checked using an ohm meter on the low scale. Twist and turn the mag plate also, to ensure the lead isn’t chafed/broken/intermittent. The same issues occur with the wiring harness that runs out of the mag plate to the coils. Those leads can get chafed/split/grounded.

Finally, and I should have lead with this, is the stop switch. Pressing the stop switch shorts both sets of points together, killing primary output. So, it is best to disconnect the two stop switch leads from the ignition harness to make sure the switch is not faulty. It is also possible that the stop leads that are connected to the breaker points are grounded/chafed onto the mag plate. So, you may want to disconnect the stop leads right at each set of points and recheck to rule out that possibility…

It is also important to realize that both sets of points must be set and working correctly, or you could lose spark to both/opposite cylinder. The primary voltage completes its path back to the driver coil through the opposite set of points that is closed….So, let’s just say one set of points was not closing properly, or perhaps oil soaked…You might lose spark to the opposite cylinder because its primary signal can’t make it back to the driver coil through the points from the other cylinder….-

This reply was modified 4 years, 11 months ago by

fleetwin. Reason: correction

1 user thanked author for this post.

July 17, 2020 at 7:23 pm #208944I don’t believe I have any motors with this ignition system, but I have saved your

excellent description on how it works, just in case! Thanks!Prepare to be boarded!

July 17, 2020 at 11:04 pm #208968Isn’t part of the trick with the low-tension system that the flywheel has two magnets?

http://www.omc-boats.org

http://www.aerocraft-boats.orgJuly 18, 2020 at 6:53 am #208982Two sets 180 degrees apart one for each cylinder, two points and condensers, two external coils and one charge coil. Not sure if that was their best idea.

2Fast4Me

July 19, 2020 at 7:47 am #209094Two sets 180 degrees apart one for each cylinder, two points and condensers, two external coils and one charge coil. Not sure if that was their best idea.

No, low tension was surely not OMC’s finest hour for sure. More complex and less reliable than regular magneto. This system can be made to work satisfactorily, but requires much more maintenance that regular magneto. The key to success is keeping the mag plate from getting worn resulting in slop. Remember to replace that plastic bushing, 322435, on the engines that use it. I’m pretty sure this engine does not use the plastic bushing though…

Dan Anderson reminded me that this system came about so a small alternator could be added to these engines. CDII solved all these issues…July 19, 2020 at 12:18 pm #209132What you haven’t mentioned is whether or not you installed new spark plug wires and connectors when you changed out the coils. Going by the amount of corrosion in your first photo, I’m willing to bet the spring terminals inside the spark plug boots are badly corroded to or are making a poor connection with the wires core causing no continuity in the wires which in turn is causing the no spark situation.

1 user thanked author for this post.

July 19, 2020 at 2:19 pm #209147The new coils have spark plug wire with it

-

This reply was modified 4 years, 11 months ago by

Mumbles.

Mumbles.

July 19, 2020 at 3:50 pm #209167Yes, I remember you posting about the new coils. But, Mumbles post is a good reminder for the rest of us when checking coil secondary resistance. Those poor/rusted connections often show up as an infinite resistance reading on the high ohms scale…A good coil could be discarded only because of a poor/rusted plug boot/terminal…

July 20, 2020 at 9:09 am #209220Hello,

Found an E-bay of good use Johnson Evinrude 20 Hp Ignition Plate Coil 581131 Driver Coil 581130 Stator of 1975 model and ready for use.

I am thinking about to swap it since it has two (2) charge coils. Is it the new update or improvement from 1975 model?-

This reply was modified 4 years, 11 months ago by

Evinrude 25.

-

This topic was modified 4 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.