Home › Forum › Ask A Member › 1955 Evinrude 15HP shifting problem

- This topic has 24 replies, 10 voices, and was last updated 5 years, 1 month ago by

crosbyman.

-

AuthorPosts

-

May 22, 2020 at 5:43 pm #203795

Ok here is a different one. Newly rebuilt motor shifts find F-N-R while not running. Minute I start it, it goes into forward only and I have no response at all from the shift lever. Shift lever tight on shift shaft assembly, good gears, and new shift dog. Upper and lower brass shift rod connector tight.

One note it’s a mix of parts (1955 Evinrude 15HP and a 1957 Johnson 18HP). If I mixed up the shift rod cradle assemblies could that cause a problem like this?

Any ideas before I pull the motor block off the exhaust housing, and tear apart the lower unit?

Thanks,

Bob DMay 22, 2020 at 6:35 pm #203798Remove the access cover from the side of the mid-section and see if you can move the shift rod up and down with a pair of needle nose pliers. (should not)

May 22, 2020 at 8:57 pm #203802Did you have the gearcase apart? Perhaps the shift fork fell out of the clutch dog cradle…Sure hope I’m wrong about this.

Hope you will find a simpler problem when you remove the shift rod access cover…May 22, 2020 at 9:44 pm #203807Hi Frank, i opened the access cover and can get about 1/2″ of play from the shift rod. Enough to cause problems?

Don, had the gear case apart, checked the gears, put a new shift dog in along with all new seals and pressure tested it.

I guess I’m going to have to open it up again. Maybe the clutch dog cradle as you suggested? I didn’t replace that when I did the initial rebuild. One step forward, three backward. Oh well, will keep everyone posted.

Thanks,

Bob DMay 22, 2020 at 10:11 pm #2038101/2″ slop in the shift rod tells the truth. Off with the powerhead to fix it.

May 22, 2020 at 10:31 pm #203813Ok Frank will do. I’ll post some pics when I get it apart.

So you are thinking some slop in the shift rod lever part # 303720? Same problem Outboardnut just had on his 55 25HP? Interesting.

Sounds like a recall OMC should have had back in the 50’s , ha ha.

Bob DMay 23, 2020 at 9:30 am #203823Please don’t pull that gearcase apart based on my “guess”….Check everything else first. Most often the issue is an improperly installed/loose shift rod connector or slop in the shift handle linkage. I really like Mumbles method of painting the beveled parts of the shift rods to help ensure proper alignment before tightening the connector. Keep in mind the SS connector bolts are easily stripped also…

You did mention using pieces from two different year engines, did you check the parts books to ensure these engines used the same pieces? I seem to remember that the 55 engines had a slightly different skeg that connected to the shift fork linkage without the conventional pivot screw that was used in later years. Perhaps the shift rods were different also….

Did you check the set screw on the shift handle? There will be considerable slop in the system if the screw is loose. Perhaps the screw is rusted/seized/loose, you shift be able to see if the shift handle is slipping around on the shaft…

May 23, 2020 at 10:02 am #203824Ok Frank will do. I’ll post some pics when I get it apart.

So you are thinking some slop in the shift rod lever part # 303720? Same problem Outboardnut just had on his 55 25HP? Interesting.

Sounds like a recall OMC should have had back in the 50’s , ha ha.

Bob DYes 304720 (376564) is my first suspicion, they often come loose on the shift shaft. However that is not the only common problem. The shift shaft often get up and down slop in the hole it passes through. And of course,, the handle adjustment is often tampered with in an effort to “fix” the slop. You need to inspect the whole thing.

Matter of fact, omc did change the inner lever in later Big Twins like the 33hp, I don’t remember if that new design can be adapted to the fastwin series or not. The upper shift rod is part of the deal. New design shown in following picture

May 23, 2020 at 10:58 am #203830May 23, 2020 at 5:55 pm #203846First off, big thanks to all for the comments, suggestions, and diagrams.

OK I pulled the power-head and here is what I found:

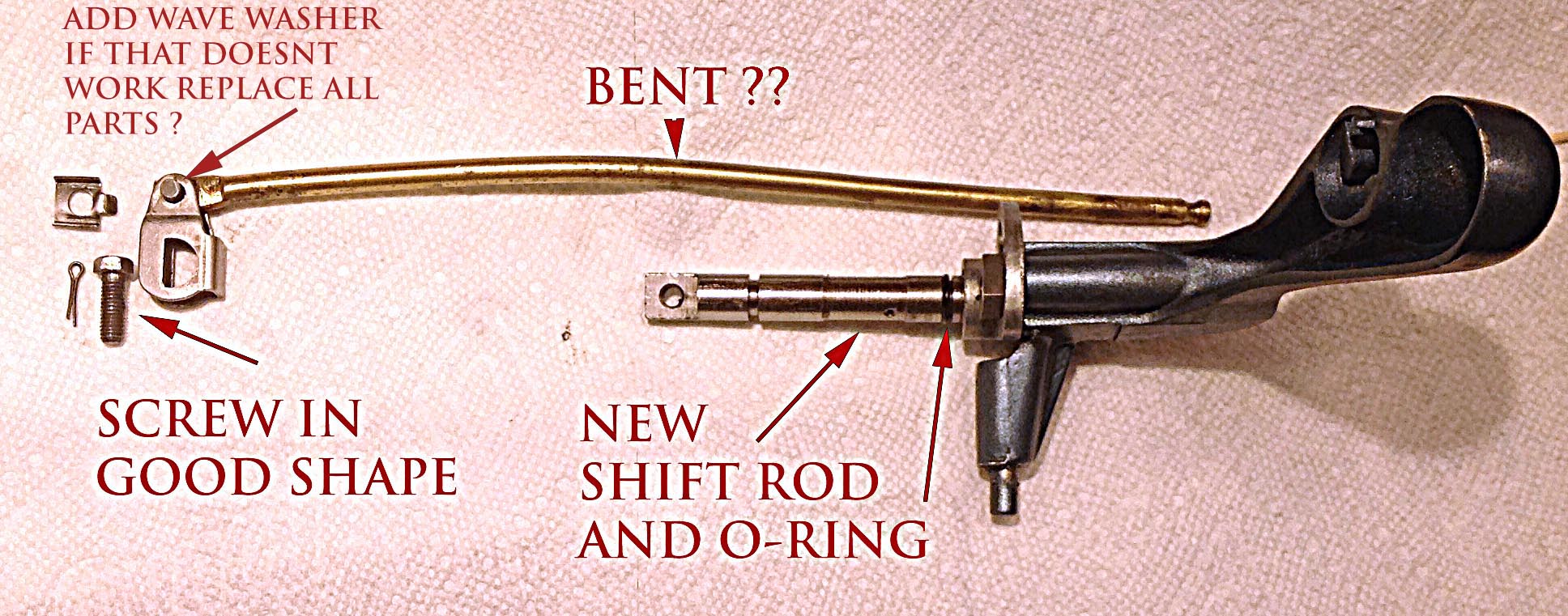

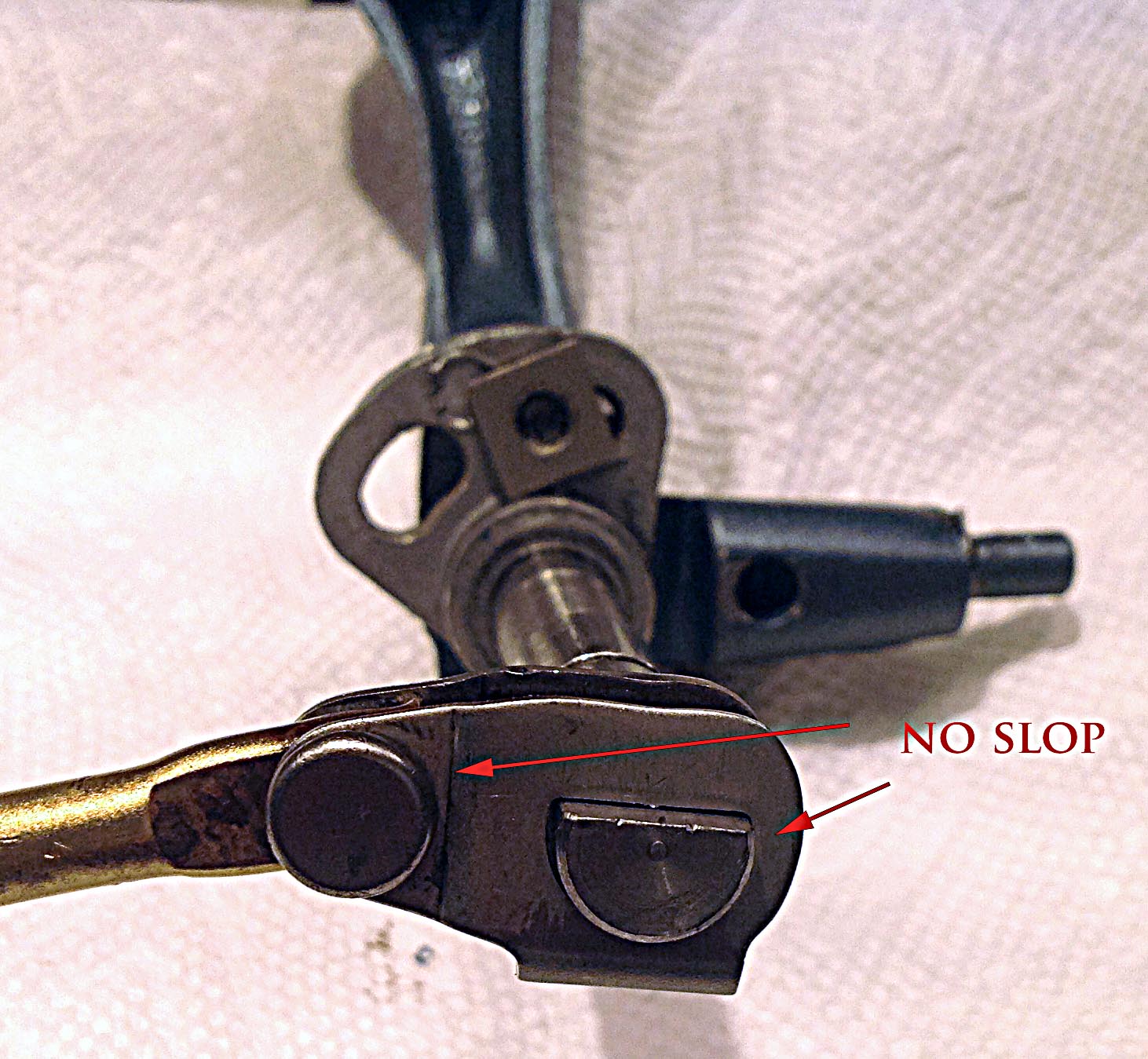

1. 304720 (376564) no slop. Stainless screw in good shape.

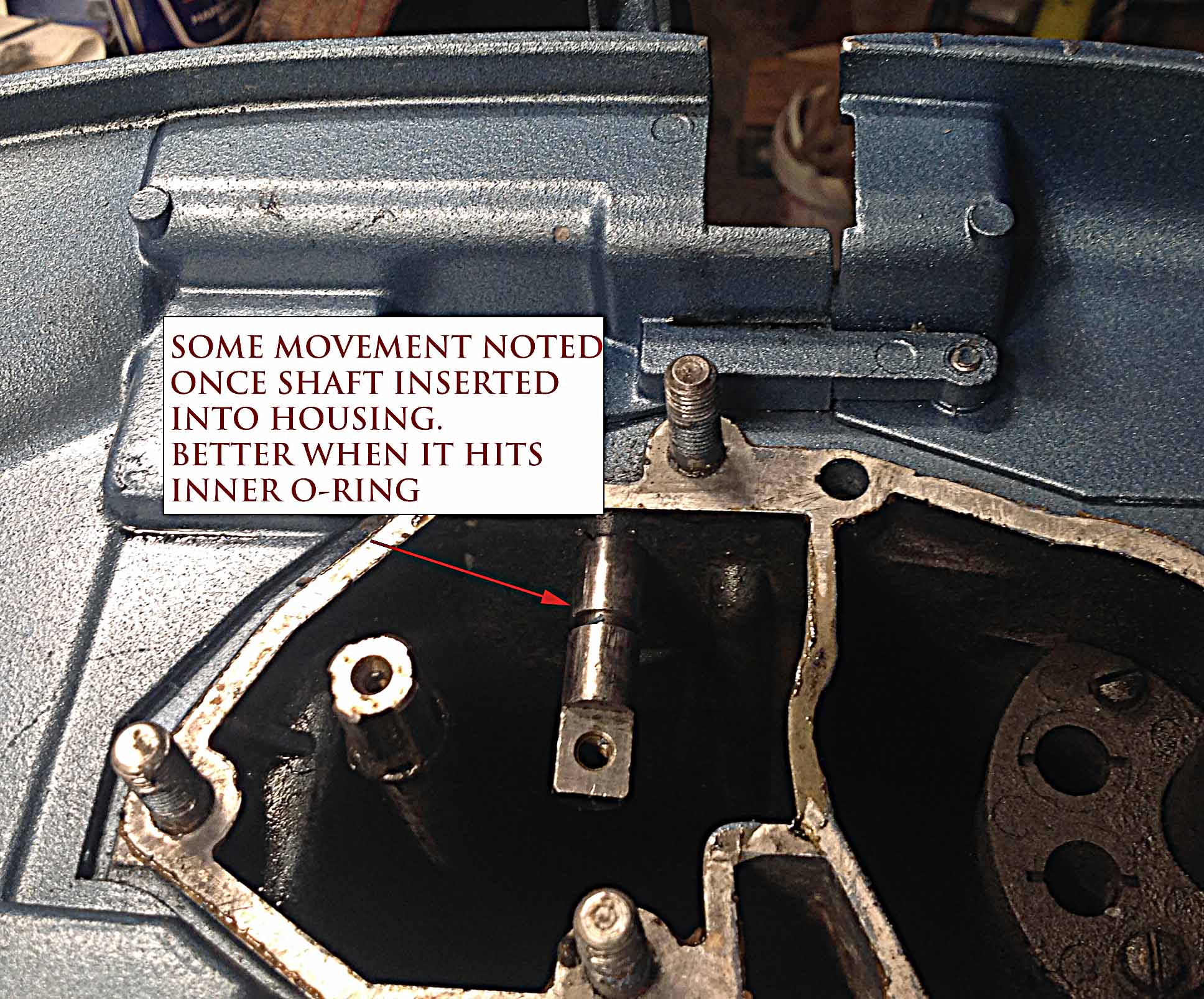

2. A bit of looseness where the shift shaft was passing through the housing. Probably where i got my initial looseness when I did the Frank plier access cover test. Got better when it hit the o-ring. Maybe

add a second o-ring on the shift shaft closer to the inside of the housing to minimize movement?

3. Upper brass shift rod was bent. When i first disassembled the motor I thought that was the way that the factory made them, when all of this happen, i checked online and the rod should be straight as an arrow. Could this be the smoking gun, throwing off the geometry of the shift mechanism?

4. The hole in the middle of the exhaust housing that the shift shaft passes through looks good, no slop or elongation.At this point I’m thinking I should try:

1. Straighten out the upper brass shift rod.

2. Add another o-ring on the shift rod that passes through the housing.

3. Add the spring clip that comes in the shift rod lever 376564 kit.Any other ideas are welcomed while its all apart.

Thanks,

Bob D -

AuthorPosts

- You must be logged in to reply to this topic.