Home › Forum › Ask A Member › 1988 Johnson 9.9 NO spark.

- This topic has 25 replies, 4 voices, and was last updated 5 years, 11 months ago by

mark weaver.

-

AuthorPosts

-

June 30, 2019 at 6:36 pm #178240

I took the stator plate of, took the clamp under it off to see if a wire had cut through…nothing. I took the ignition coils off the power head and tested them, they are both in spec, even if they were bad under load they would fire or at least one would cranking over. When I replaced the STATOR COIL I matched wire color code. I used the chart above that Mumbles posted and connected a ohm meter to pins B and C in the 5 pin plug and am getting an erratic reading starting at 15 ohms and go to 55 ohms up and then down and then back up. Is that normal? The outboard was never touched during the winter, just put in a shed like it had been for years before. I looked in the 5 pin plug and there is no loose pin or wire or corrosion. As for the kill switch I set my meter on continuity setting and hooked it to the ground that went to the block and the wire that goes to the 5 pin plug. with the clip in …NO continuity….clip out continuity… so that is working. The NEW power pack can only plug into the 5 pin plug one way and the two leads that go to the coils are the same color code as the old one and are hooked up properly. STILL no spark. I made up new plug wires…tested them for continuity and tried them….no spark.

June 30, 2019 at 6:48 pm #178241A note about the air gap…. I have done DOZENS of the old magneto type coils so I know to set the coil to be flush with the block under the coil laminate as not to hit the magnet when rotating so have about 10 to 12 thousands air gap. I am not new to working on these things but am stumped here.

June 30, 2019 at 7:16 pm #178242am getting an erratic reading starting at 15 ohms and go to 55 ohms up and then down and then back up. Is that normal?

No! It should be a steady reading within the given values. I think you’ve narrowed your problem down to the sensor coil or its wiring.

Just a note but the wires tend to break internally where they make a sharp bend under the cover plate holding them down to the armature plate. The outside insulation will look good but the wire inside can be broken and hanging on by a string. This might give the erratic readings. Wiggling the wires or turning the mag plate with the meter hooked will usually show a reading all over the place if

a wire is broken inside and making intermittent contact.Someone had this same issue here a while back and narrowed it down to a bad wire in this area.. I’ll see if I can find that topic and post a link to it.

June 30, 2019 at 7:26 pm #178243I think this was it.

The last reply says it all.

Click on these big letters as it is the link!

https://aomci.org/forums/topic/1977-evinrude-6hp-losing-spark/

-

This reply was modified 6 years ago by

Mumbles.

Mumbles.

June 30, 2019 at 7:53 pm #178250Ok I read the 6 HP post and that sounds VERY possible. I did have that plate off that holds the wires but just checked for chafed wires….never thought about a break. There was a zip tie near that clamp shown in the picture through the mag plate and around the wire harness so… to tight maybe…..broke a wire maybe??? Yes Mumbles I thought that reading should be a stable reading so if it is a broken wire I am down to the two going to the trigger sensor at least. Back to it tomorrow. THANK YOU to all that are taking the time to help me here, just a great place to find intelligent opinion and suggestions. As I said before this motor is GOING TO FIRE sooner….or later.

June 30, 2019 at 8:44 pm #178257Well, the sensor is the only thing you have not replaced….The resistance reading should be steady, it is just a simple winding. That being said, I would try a different ohm meter just to be sure it is not a meter issue.

As for the stop switch, I think I read that you have replaced it already, correct? In any event, even though the switch passed the ohm meter test, that is no guarantee it is OK…Arcing can still occur even with good resistance tests.

In any event, I’m guessing that your erratic sensor resistance readings are probably the issue, but just check it again with another meter to be sure. Trying to set the sensor air gap without the alignment ring is tricky, because there are no laminations to line up with the machined surfaces on the mag plate. The conventional alignment ring for the universal mag plate systems works for the CD2 systems as well….July 1, 2019 at 11:45 am #178286Removed the stator plate and clamp under it today. Shaved a tiny bit of the wire covering NEXT to the trigger sensor and have continuity from there to the 5 prong plug in BOTH WIRES no matter how much you move them….NO break in those wires. Done an OHMS test on the trigger where I bared the wires…same thing started at 14 this time and slowly one point at a time up to 55 then back down to 25 then back up. I looked at the side of the sensor that faces the magnet and it looks as if it has hit the flywheel as it looks to be scraped…. maybe…. and also one arm of the stator coil looks to have hit the flywheel SOMETIME. I did NOT move anything myself AND the owner, who I know, said it HAS NOT BEEN TOUCHED from last year. The mag plate was tight AND the flywheel nut was VERY TIGHT when I removed it. I thought there may be play in the mag plate but NO play in the mag plate when screwed down. I am wondering if something came off and got on that magnet like a screw or piece of metal or something or WHY anything under there would be hitting that flywheel….the coil and the sensor are in PERFECT position relative to the mounting blocks or guides under them perfectly flush with them and ran that way FOR YEARS. Ordered a new sensor. If no one had that flywheel off where did that little scrape come from on the coil laminate and what LOOKS like on the sensor too???

July 1, 2019 at 2:15 pm #178288This mag plate came from a running motor which got destroyed in a garage fire. The sensor coil does show some signs of contact with the flywheel but I’ve noticed that before on other motors to which run good. It doesn’t seem to affect them.

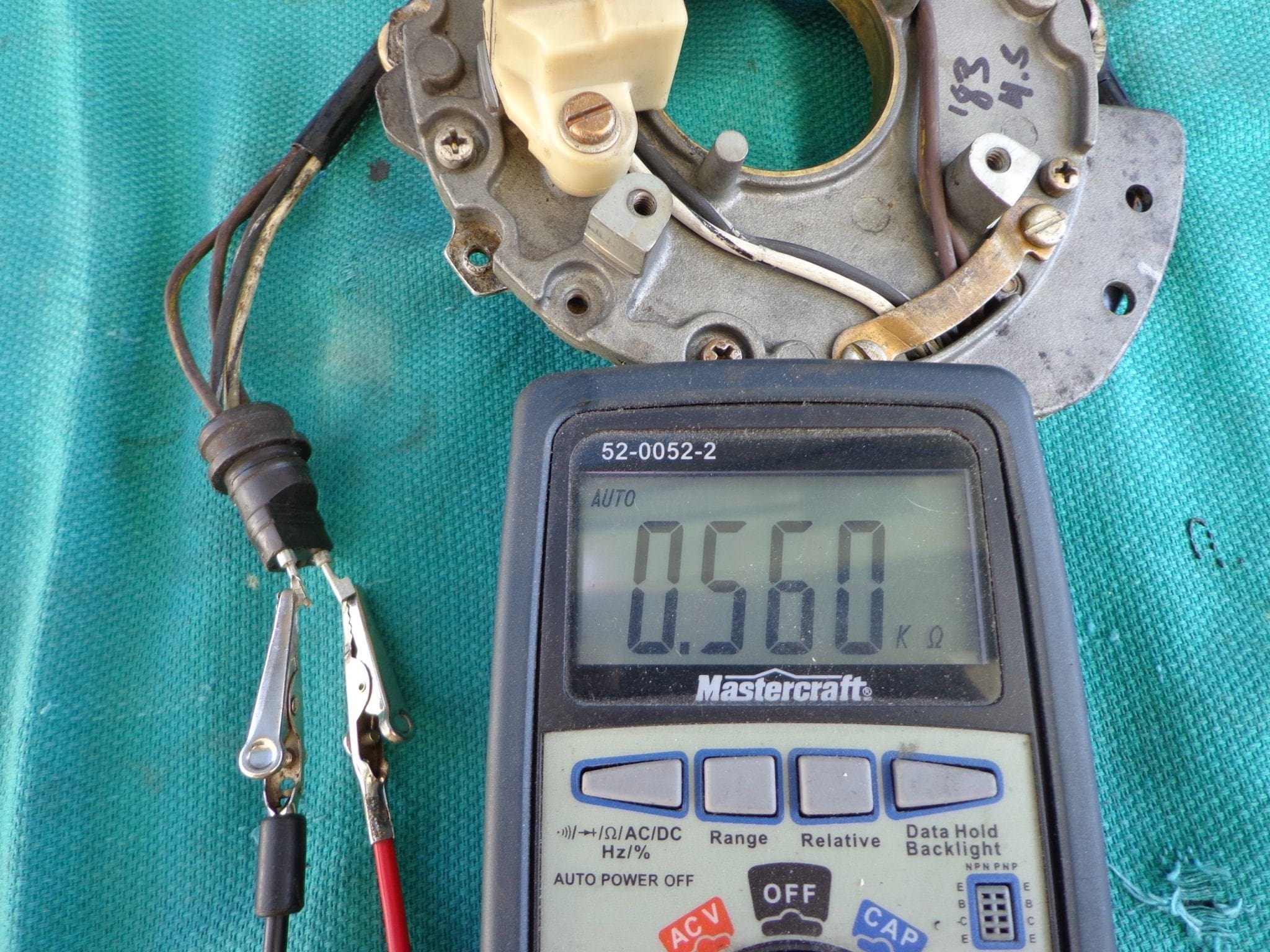

While it was on the bench, I figured I’d do and ohm test on the coils and got steady reading of 41 and 560 ohms resistance. These parts are good and fit for further use.

July 1, 2019 at 3:53 pm #178292Yep, I am getting 560 to on the coil. I checked grounds to the power pack and power head and have continuity there. I have a nearly new Fluke meter but will check with my old ebay one to be sure. I have the ring from Richard’s timing tools so will use it for sure for air gap. I will test the spark with NO wires hooked up to the kill switch, ground or E in the 5 prong plug. I ordered a new sensor and a cheap set of tools for removing the pins from the 5 prong plug. The next thing I order will be a 10 pound sledge. Thanks mumbles for the pics and ALL the help and will post when I get the sensor.

July 2, 2019 at 2:09 am #178303when I get the sensor.

Hey! just noticed that you are up north to. PM me your address and I’ll give you all the parts you need for free. Just help me out with the shipping costs is all I ask. ☺

-

This reply was modified 6 years ago by

Mumbles.

Mumbles.

-

This reply was modified 6 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.